TGB Blade 1000 Single APXUpdated a year ago

Please read the below Important Information relating to Safety & Fuel Tuning by clicking on the text below.

Important Information - Safety

WARNING: Before starting the installation of any ATV, UTV, or SXS aftermarket parts, it is important to prioritize safety. Make sure you are using suitable protective gear, this includes but is not limited to safety goggles, gloves and protective clothing.

Ensure your vehicle is on flat, stable ground. Installing parts on uneven or unstable surfaces can potentially lead to injury or damage to the vehicle. The vehicle should be turned off and cooled down before proceeding with the installation. Attempting to install parts on a running or hot vehicle can result in burns or other serious injuries.

After completing installation, it is important to inspect and check the tightness of any and all nuts, screws, and bolts. Failure to properly secure these fasteners can lead to component failure or detachment during riding, posing significant safety risks to both the rider and bystanders. The vehicle should be warmed up and subsequently cooled down to account for any thermal expansion or contraction effects that may affect the tightness of the fasteners.

It is crucial to inspect and tighten screws and bolts as necessary after initial rides, as vibrations and stresses during operation can cause fasteners to loosen over time.

It is important to pay close attention to the condition of the exhaust system and undertake the necessary measures to maintain optimal performance. Failure to properly maintain the exhaust system can result in reduced engine performance and potential safety hazards. Remember to repack exhausts as necessary to ensure efficient exhaust flow and minimize any potential restrictions that could adversely affect performance.

Prior to starting the installation process, it is important to thoroughly read all provided instructions to familiarize yourself with the installation procedures and any specific requirements or precautions. Failure to follow the instructions could result in improper installation or component failure.

Please check your local laws and regulations governing the use of aftermarket parts on your vehicle. Failure to comply with these regulations can result in legal repercussions, fines, or other penalties. Therefore, it is important to research and understand the applicable laws and regulations before installing aftermarket parts on your vehicle. Always ensure that any modifications made to your vehicle comply with local regulations.

Please check and read the full Warranty Information that can be found at:

Important Information - Fuel Tuning

The use of an aftermarket performance exhaust requires a crucial step - EFI tuning. RJWC Powersports exhaust systems must be accompanied by a proper re-flashing or use of an EFI Tuner to prevent the engine from running lean, which can result in engine damage. To guarantee a correct air to fuel mixture, make sure to adhere to the manufacturer’s recommended settings for your fuel tuner.

Neglecting to properly tune the engine using an EFI tuner when using an RJWC Powersports exhaust will void the exhaust warranty. Any problems arising from the engine not running correctly, such as a lean condition or incorrect air/fuel ratio, will not be considered a valid warranty claim.

Please note that if your vehicle differs from the base model, additional modifications such as a different tune, turndown pipe, or other adjustments may be necessary to achieve a proper fit and optimal performance. All RJWC Powersports exhausts are designed and tested on stock-equipped vehicles.

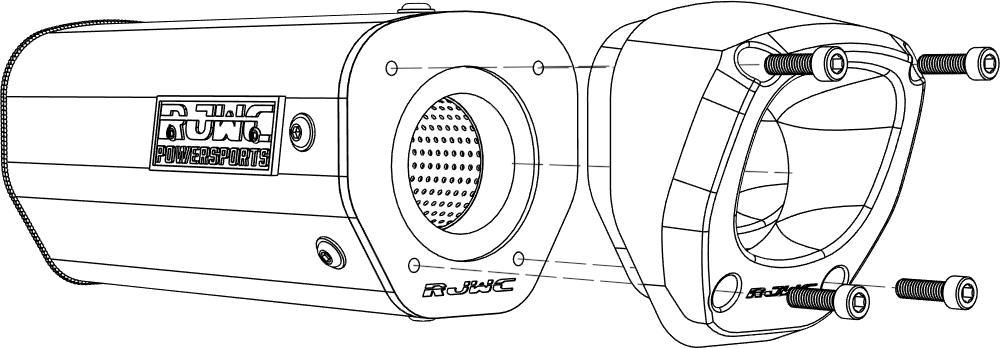

Spark Arrestor & Shim Ring Installation

The Spark Arrestor and Shim Ring are not pre-installed, they can be found in the Hardware Kit.

To install the Spark Arrestor, start by removing the End Tip. Unscrew the four M6x20 Cylinder Screws in the End Tip to remove it.

There is a small circular groove in the End Cap, in this groove you need to place the Shim Ring first, then the Spark Arrestor.

With the Shim Ring and Spark Arrestor in place, reinstall the End Tip by screwing back in the M6x20 Cylinder Screws.

Removing the Stock Exhaust

Remove the heatshield from the section between the Header and the Stock Muffler Pipe. Remove the two bolts holding the stock exhaust in place. Loosen the clamp that seals the Header Pipe to the Muffler Pipe and remove the stock exhaust.

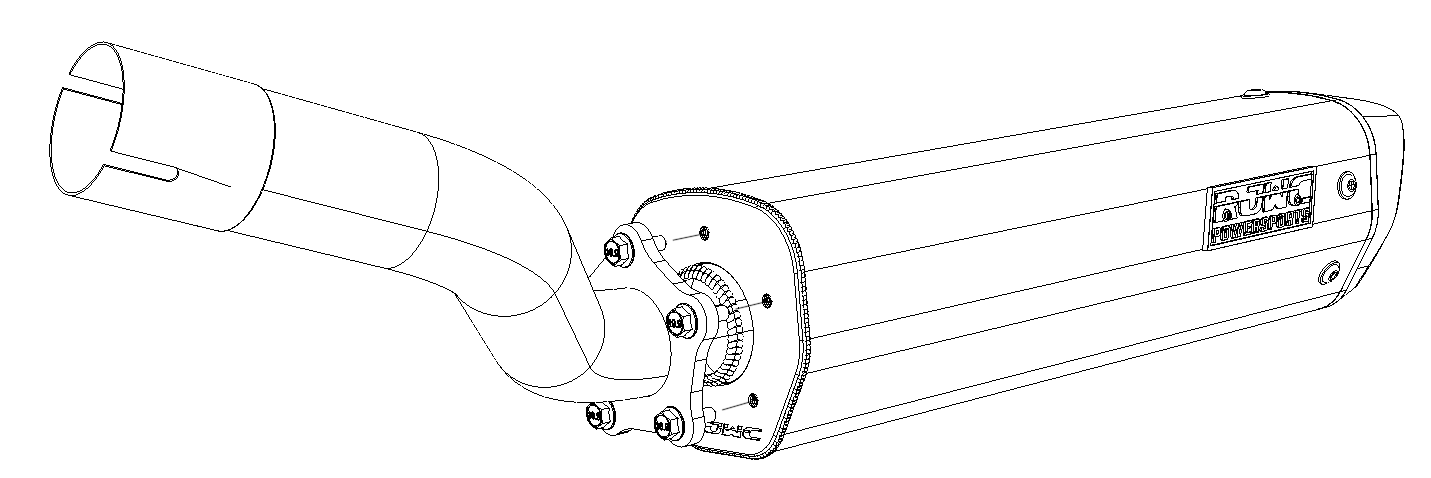

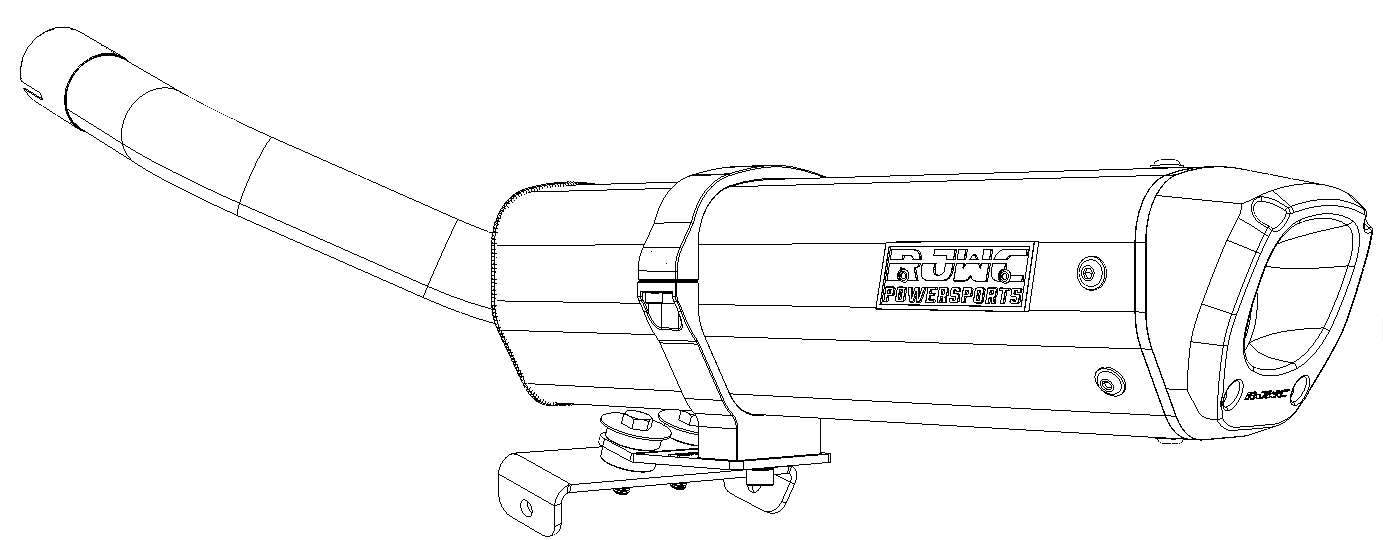

Installing the APX Exhaust

Place the G2 Gasket in-between the pipe and the APX can, lining up the holes between all three. Use 5x M6x20 Hex Flange Screws to secure the pipe to the APX.

The G2 Gasket should be tightly sandwiched between the pipe flange and the APX can.

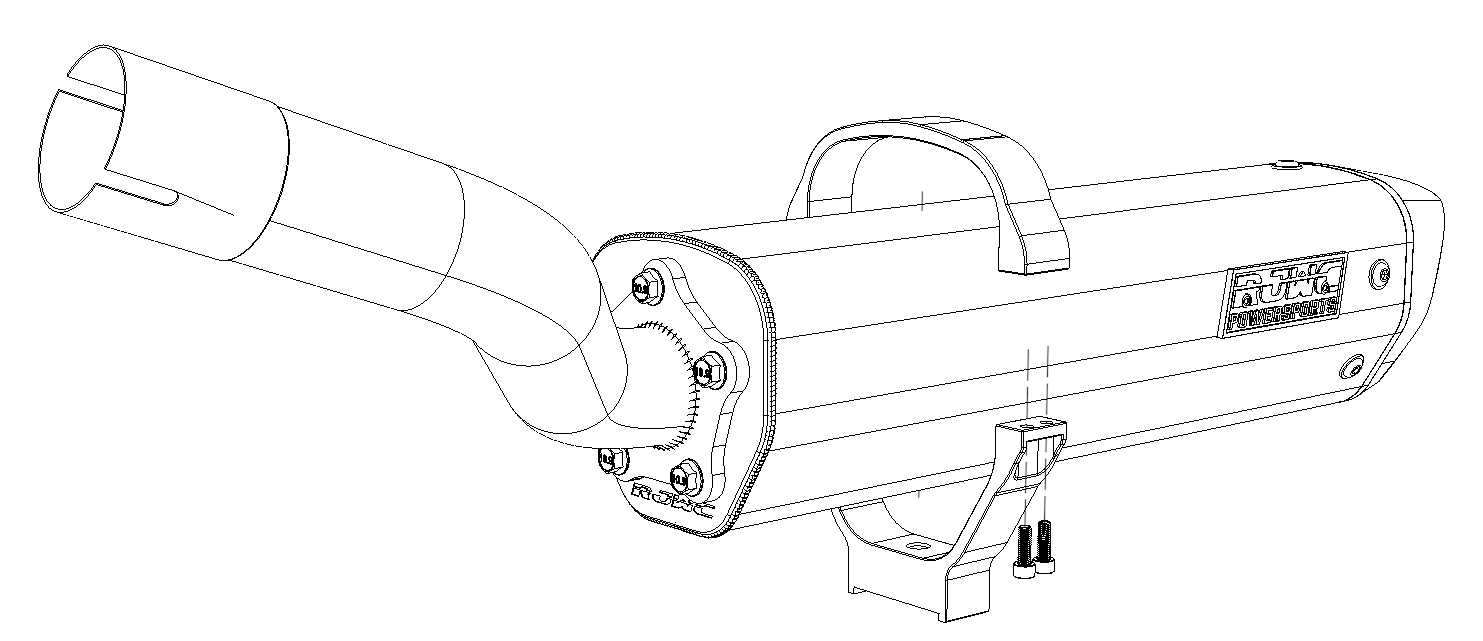

Place the Upper Clamp and Lower Clamp around the muffler. The Upper Clamp is smooth and the Bottom Clamp has a threaded hole. Use the 4x M5x16 Cylinder Screw and the 4x M5 Washer to secure the clamps in place.

Do not tighten these fully, as they may need to be adjusted for the positioning of the muffler.

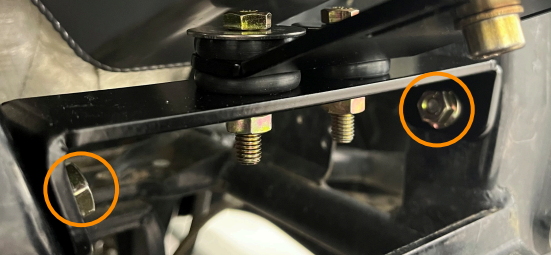

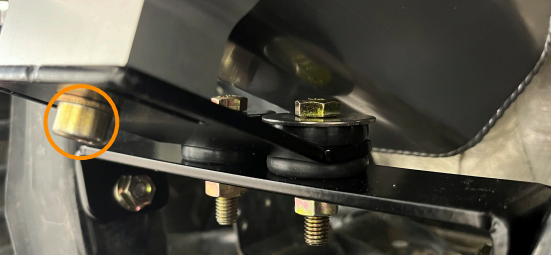

Set the muffler to the side and install the long TGB Bracket. Use 2x M8x30 Hexagon Screws and 2x M8 Nuts with Collar to secure the long bracket to the vehicle frame at the circled points.

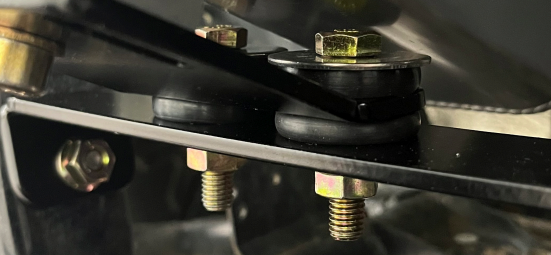

Use 2x M8x40 Hexagon Screws and add 1x Washer 8.4x35 to each screw. Push 1x Rubber Bushing onto each screw. Slide the two Hexagon Screws into the flat part of the angled TGB Bracket.

Place 1x Rubber Bushing onto the Hexagon Screws to ‘sandwich’ the angled TGB Bracket.

Insert the two screws into the TGB Long Bracket that was previously installed, and use 2x M8 Nuts to secure everything in place.

Hold the APX Exhaust in place and use 1x M8x20 Cylinder Screw and 1x Washer 8.4 to fasten the APX Exhaust to the angled section of the TGB Bracket in the circled area.

Align the Header Pipe to the Muffler Pipe and use 1x Clamp 45-50mm to secure the pipes together. Line this up to where the pipes connect to prevent any leaks.

With the exhaust mounted you need to tighten all screws in place. You should start your vehicle, allow the exhaust to get warm and shut the machine down to cool. When it is cool, double check all screws and bolts and retighten them.

After your first ride, double check all screws and bolts and retighten.

You have now completed the installation of the TGB Blade 1000 Single APX.

If you have any questions, or need any help please send an email to [email protected]